Precision engineered protection

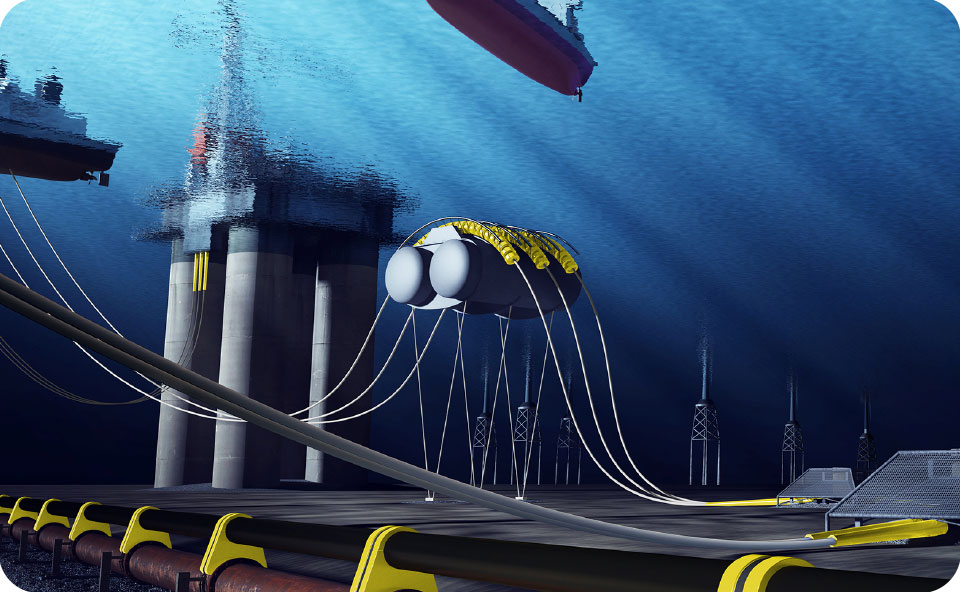

Many of the world’s leading names in energy production rely on Kaylan Offshore to manufacture their high-quality custom mouldings, specifically formulated for use in the harshest underwater environments.

Working with the right material in the harshest environments

Kaylan Offshore processes a wide range of materials, for a variety of products and applications, currently including:

• MDI • TDI • TPU

• Polyether • Polyester • Caprolactone • Polycarbonate • Aliphatic

• Mercury-free • High Temperature

• Hardness range available from Shore 10A through to Shore 85D

• Component weights cast up to 1500kgs

Tried, tested and quality assured

Proven to consistently outperform the more traditional materials, Kaylan is relied upon not only in the onshore, offshore and subsea sectors, but also in such demanding areas as mining and construction, aerospace and motorsport. That’s why every part is rigorously examined in our state-of-the-art testing facility.

Results show that our products not only excel in extreme conditions, but also under extreme pressure, stress, flex and compression. This strict adherence to the very highest of quality standards is what ensures that every Kaylan Offshore solution is ‘fit for purpose’.

Environmental credentials

Kaylan Offshore is committed to minimising the impact on the natural environment, which is why our purpose-built factory is designed with efficiency in mind and features: solar panels, computer-controlled heating and lighting systems that save energy and reduce our carbon footprint. We are committed to the recycling of raw materials, packaging and solvents, and also process the latest range of mercury-free systems to help protect the environment.